Products

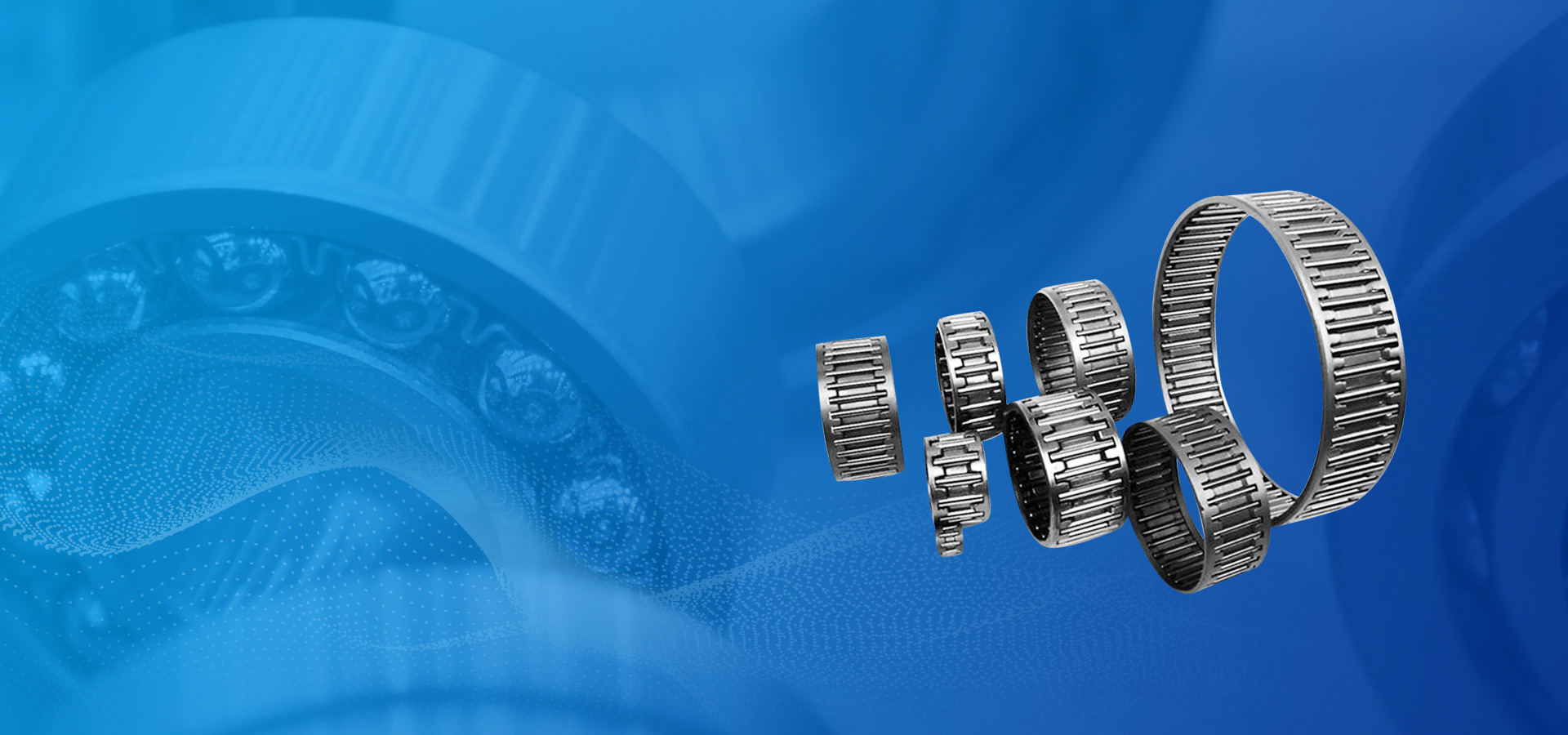

The company is mainly engaged in the manufacture, processing and sales of Bearing, Roller, Roller pin and mechanical parts.

Bangde Bearing Roller

Committed to becoming the world's trusted Bearing Roller manufacturer

Changzhou Bangde Bearing Roller Co., Ltd. It is a private enterprise company focusing on the transportation/logistics/transportation industry, mainly engaged in the manufacturing, processing and sales of Bearing, Roller, Roller pin and mechanical parts. Self-operated and agent import and export business of all kinds of commodities and technologies (projects subject to approval according to law can only be carried out after approval by relevant departments) and a professional company registered and established by the State Administration for Industry and Commerce. With the business philosophy of standardization, professionalism, innovation and win-win, efficient and considerate service, the enterprise spirit of unity and cooperation, dedication and responsibility, service dedication, truth-seeking and enterprising, the company always implements the goal of pursuing the interests of partners and wholeheartedly provides reliable protection for partners.

Company establishment

Production Line

OEM experience

BLOG

Record enterprise development information, let wonderful sharing

Core advantages

Our company specializes in Bearing, Bearing Roller sales and production, has a perfect production system, and thoughtful service sales team.

Explore Details →

Production line capacity

Bond Bearing has more than 10 production lines, with an annual output value of about US $50 million to US $0.1 billion.

OEM Capability

Bangde Bearing Roller has more than 10 years of OEM experience and can meet the different customization needs of various customers.

Quality Control

We have a quality inspection team of about 30 people to strictly inspect the products and ensure the quality.

Online message

Welcome to leave your information to get in touch with us!

Manager Wang: +86-13861268538

Manager Jiang: +86-13961180287

E-mail: 13861268538@139.com

Address: No. 209, Huaxing Road, Jintan District, Changzhou City, Jiangsu Province, China.

Copyright © 2024 Changzhou Bangde Bearing Roller Co., Ltd.