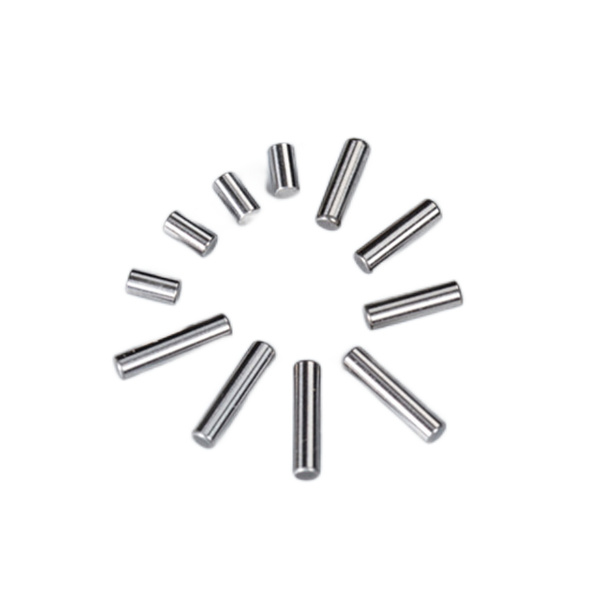

2-Series Roller Bearing

Key words:

Bearing | Roller | Roller pin | Pin shaft

Classification:

Description

Name Roller material GCR15, stainless steel hardness HRC60-65 excircle tolerance 2um length tolerance 30um verticality ≤ 15um end face runout ≤ 15um roundness ≤ 1um surface roughness ≤ Ra1umGCr15 refers to a high carbon chromium Bearing steel with less alloy content, which has high hardness, uniform structure, good wear resistance and high contact fatigue performance after quenching and low temperature tempering. Areas of application Bearing rollers, jet nozzles of turbojets, plungers, flaps, bushings, etc.

The Roller Bearing consists of a retainer, a Roller, and a guide sleeve, and is a separable Bearing that can be separated from another Bearing ferrule. This kind of Bearing is easy to install and disassemble. Compared with other types of Bearing with the same external dimensions, Roller Bearing has the characteristics of high load, low noise and high speed. Moreover, the friction between the rolling body and the flange of the track ring is small, which is suitable for high-speed rotation. Then, learn about the categories and characteristics of Roller Bearing together below!

Roller Bearing, like other kinds of Bearing, are divided into different categories. In order to better understand the Roller Bearing, the types and characteristics of Roller Bearing will be explained in detail.

In a single-row Roller Bearing, the Roller is usually guided by a flange of any one of a set of Bearing. The flange is combined with a specially designed and surface treated Roller end to provide improved lubrication, reduced friction, and reduced Bearing operating temperature. The single-row Roller Bearing can withstand heavy radial loads and high speeds. These Bearing are manufactured in several different designs, but the main difference is the rib structure.

The double-row Roller Bearing has compact structure, strong carrying capacity and high rigidity. Therefore, these Bearing are mainly used in machine tools, rolling mills, rollers, grinders and large gear boxes. The double-row Roller Bearing has a cylindrical hole and a conical hole; the internal clearance can be fine-tuned when installing the conical hole Bearing, simplifying the structure of the positioning device.

Full-loaded Roller Bearing can withstand greater loads. There are single-row and multi-row structural designs. This type of Bearing is suitable for medium and low speeds and places with larger loads, such as construction machinery, vehicles, steel, lifting machinery, etc.

四列 Roller Bearing

The four-row Roller Bearing is mainly used for rolling mill roll necks and bears huge loads. This kind of Bearing usually adopts surface quenching carburizing steel to improve wear resistance and impact resistance, and the cage is usually mechanical planing steel cage or column cage.

Name | Roller |

Materials | GCR15, stainless steel |

Hardness | HRC60-65 |

External circle tolerance | 2um |

Length tolerance | 30um |

Verticality | ≤ 15um |

End-face runout | ≤15um |

Roundness | ≤ 1um |

surface roughness | ≤ Ra1um |

GCr15It refers to a high-carbon chromium Bearing steel with less alloy content. After quenching and low-temperature tempering, it has high hardness, uniform organization, good wear resistance and high contact fatigue performance.

Application field Bearing roller,turbojet engineNozzle, plunger, valve, bushing, etc.

More Products

Product inquiry

We will contact you within one working day. Please pay attention to your email.

Online message

Welcome to leave your information to get in touch with us!

Manager Wang: +86-13861268538

Manager Jiang: +86-13961180287

E-mail: 13861268538@139.com

Address: No. 209, Huaxing Road, Jintan District, Changzhou City, Jiangsu Province, China.

Copyright © 2024 Changzhou Bangde Bearing Roller Co., Ltd.