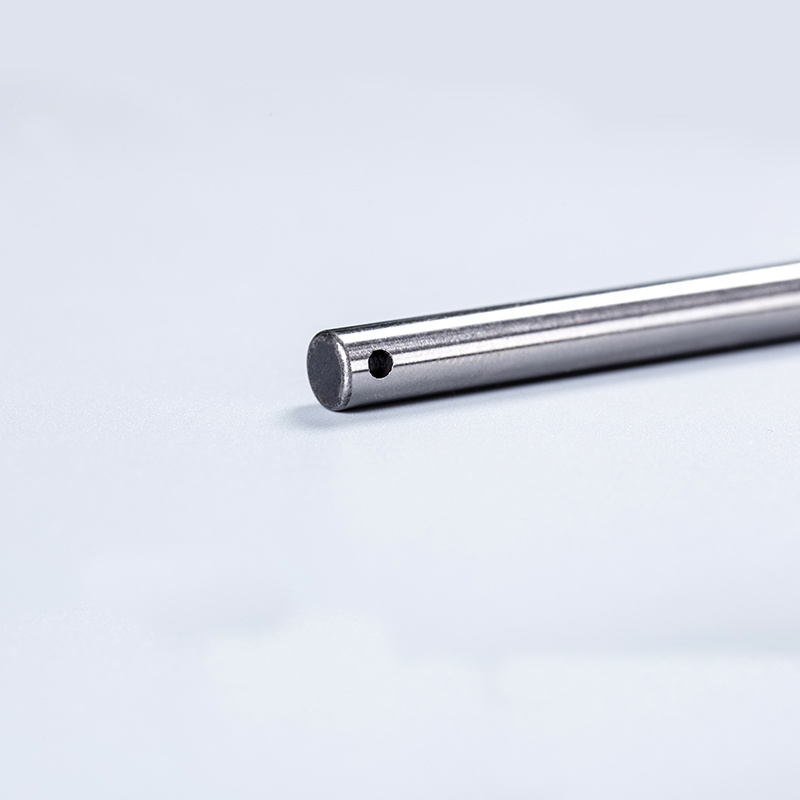

What are the maintenance and lubrication methods of one-way Roller pin Bearing

Release time:

2022-05-31

If you want to make单向Roller pin BearingThe service life is longer, then we must learn how to maintain单向Roller pin Bearing.单向Roller pin BearingWhat are the maintenance methods?What?

1,Prevent the intrusion of pollutants and dust, reduce the relative movement of the rolling element and the raceway, and reduce wear;

2,Regularly add lubricating grease to ensure good lubrication effect;

3,Oil-air, oil mist or spray lubrication can be used to improve cooling conditions;

4,Further strengthen and improve the cleanliness of the lubricating oil, which can better extend单向Roller pin BearingFull load life;

5,Maintain full load单向Roller pin BearingThe cleanliness, high cleanliness Bearing low vibration speed, low wear and tear, which can improve the service life of the Bearing.

Since want to maintain good单向Roller pin Bearing, so what are its lubrication methodsWhat?

1、单向Roller pin Bearinggrease lubrication

单向Roller pin BearingUsing grease as the lubricating medium has the advantages of low fluidity of the grease, not easy to leak, and the formed oil film has good strength, which is more conducive单向Roller pin BearingSealing use. At the same time,单向Roller pin BearingGrease lubrication can also extend the maintenance time of lubrication and make Bearing maintenance easier.单向Roller pin BearingLubrication with grease also has disadvantages. Compared with lubricating oil, the friction torque of lubricating grease is greater, so it is necessary to run at high speed.单向Roller pin BearingNot very applicable. In addition, the cooling performance of grease lubrication is poor. If单向Roller pin BearingAdd too much grease,单向Roller pin BearingIt may overheat by stirring the lubricant.

2、单向Roller pin Bearingoil lubrication

单向Roller pin BearingThe use of oil lubrication can achieve a good cooling effect, especially for high working temperature单向Roller pin Bearing.单向Roller pin BearingThe viscosity of the lubricating oil used is about0.12~0.2 cm/s, if单向Roller pin BearingThe load is large and the working temperature is high, so high-viscosity lubricating oil should be selected, and the speed is faster.单向Roller pin BearingSuitable for low viscosity lubricants.单向Roller pin BearingThe disadvantage of oil lubrication is that oil lubrication requires the Bearing to maintain a good sealing state to avoid lubricating oil leakage. In addition, oil lubrication requires a complex oil supply device, which is not as convenient as grease in operation and use.单向Roller pin BearingThe maintenance workload.

Key words:

Roller pin,Roller pin Bearing

Previous Page

Recommend News

Introduction of Bearing roller

2022-08-19

Process Development of Bearing Roller

2022-08-04

Introduction to Bearing Roller

2022-07-20

Online message

Welcome to leave your information to get in touch with us!

Manager Wang: +86-13861268538

Manager Jiang: +86-13961180287

E-mail: 13861268538@139.com

Address: No. 209, Huaxing Road, Jintan District, Changzhou City, Jiangsu Province, China.

Copyright © 2024 Changzhou Bangde Bearing Roller Co., Ltd.